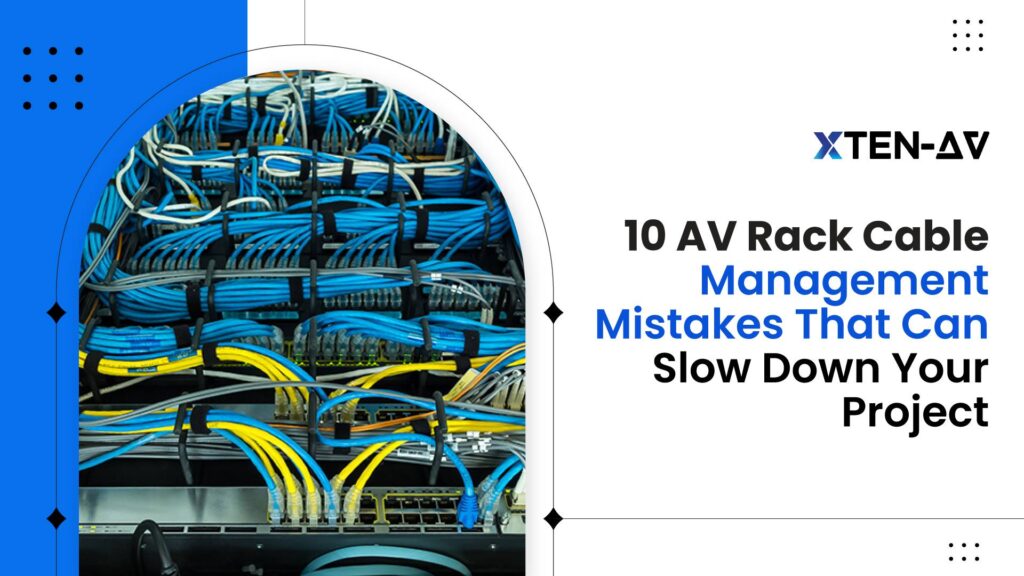

10 AV Rack Cable Management Mistakes That Can Slow Down Your Audio Visual Project

Vibhav Singh

Published 09 May 2025

Messy cables in your AV rack don’t just look bad; they can seriously compromise your system’s reliability. Poor AV rack cable management often causes hard-to-trace troubleshooting issues, signal drops, blocked airflow, and system downtime. In short, a disorganized rack turns routine maintenance into a time-consuming challenge and reduces overall system performance.

That’s why professional AV teams rely on rack management software like XTEN-AV. With intelligent automation, precise cable labeling, and standardized documentation, these tools streamline the entire AV rack setup process. The result? Faster, cleaner installations that are easier to maintain and meet project deadlines with confidence.

In this guide, we’ll break down the 10 most common AV rack cable management mistakes and how you can avoid them using the right tools and techniques to keep your projects efficient, scalable, and client ready.

The all-in-one solution for your AV needs

Transform your audio-visual experience with XTEN-AV.

No Credit Card required

Key Takeaways

- Poor labeling, wrong cable lengths, or missing documentation cause downtime, troubleshooting delays, and system failures in AV racks.

- Use Velcro instead of zip ties. Keep power and data cables separate. Plan for future expansion. Always test cables after installation to ensure long-term performance.

- XTEN-AV offers automated design tools, real-time documentation, and smart cable management. It helps AV professionals streamline projects, avoid errors, and scale confidently for future upgrades.

Don’t Let These Cable Mistakes Derail Your AV Rack Cable Management

Keeping cables organized in an AV rack isn’t just about making things look perfect. It improves system performance, makes maintenance easier, and simplifies future upgrades. Here are common AV cable management mistakes, the issues they create, and how to stop them from delaying your project.

Failing to Label AV Cables Properly

Without clear AV rack cable labeling, technicians waste hours tracing cables and risk mistakes during repairs or upgrades. This leads to more downtime and frustration.

The solution is a standard labeling system. Use durable tags on both cable ends, color-coding or alphanumeric IDs for quick ID, and keep detailed records.

XTEN-AV simplifies this by automatically generating labels and cable lists, reducing errors, and keeping systems running smoothly.

The all-in-one solution for your AV needs

Transform your audio-visual experience with XTEN-AV.

No Credit Card required

Using Excessive Plastic Zip Ties Instead of Velcro

Many AV rack installers make the mistake of using too many plastic zip ties to organize cables, but this can cause problems over time. Pulling zip ties too tightly compresses and deforms cables, damages their internal structure, and causes signal degradation, especially in high-density or sensitive installations.

That’s why it’s better to use Velcro straps. They are flexible, reusable, and can be easily adjusted, ensuring better performance and easier maintenance.

Overcrowding Cables in the Audiovisual Rack

Overcrowding an AV rack with too many cables can cause major issues: cable entanglement, restricted airflow, and internal heat. These conditions lead to signal degradation, equipment failure, and unplanned downtime; ultimately, performance and reliability suffer.

To prevent these problems, you need to plan your rack cable layout. Use Velcro straps to bundle cables securely but flexibly. Keep the correct bend radius and leave enough slack for future changes.

XTEN-AV makes all of this easier with tools that help in AV rack organization. You create exact cable layouts. The labeling of AV system wiring is automatic and updates documentation instantly. This keeps your rack clean and ready for upgrades.

Failing to Separate Power and Data Lines

Separating power and data cables in AV racks is crucial. It prevents signal issues, electromagnetic interference, safety risks, and system downtime. This confusion will further slow down your project when troubleshooting and maintenance are more complex.

The smart way to do proper cable management is by keeping power and data cables separated from the start. If they must cross each other, make sure they do so at right angles to reduce interference.

Use high-quality shielded cables as they block interference and maintain clear, organized cable paths. Document your cable management best practices and update them as changes occur to ensure long-term reliability.

Not Planning Rack Cable Lengths Properly

Inadequate planning of cable lengths leads to overcrowded racks, excess slack, and poor organization, making maintenance and upgrades difficult. Long cables create clutter and obstruct airflow, while short ones risk strain or disconnection, causing signal issues.

First, measure the exact distances between AV equipment and rack connections before installation. Add slack for flexibility and movement. Use adjustable ties and structured pathways to manage cables. This helps maintain airflow, protect signal quality, and keep the AV rack space clean and scalable.

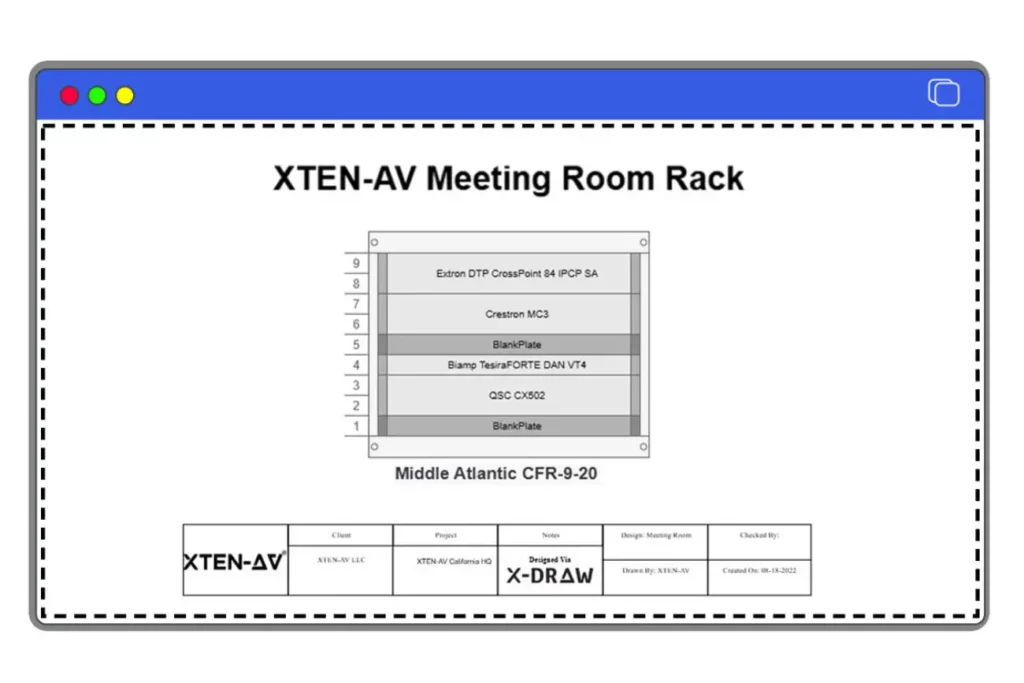

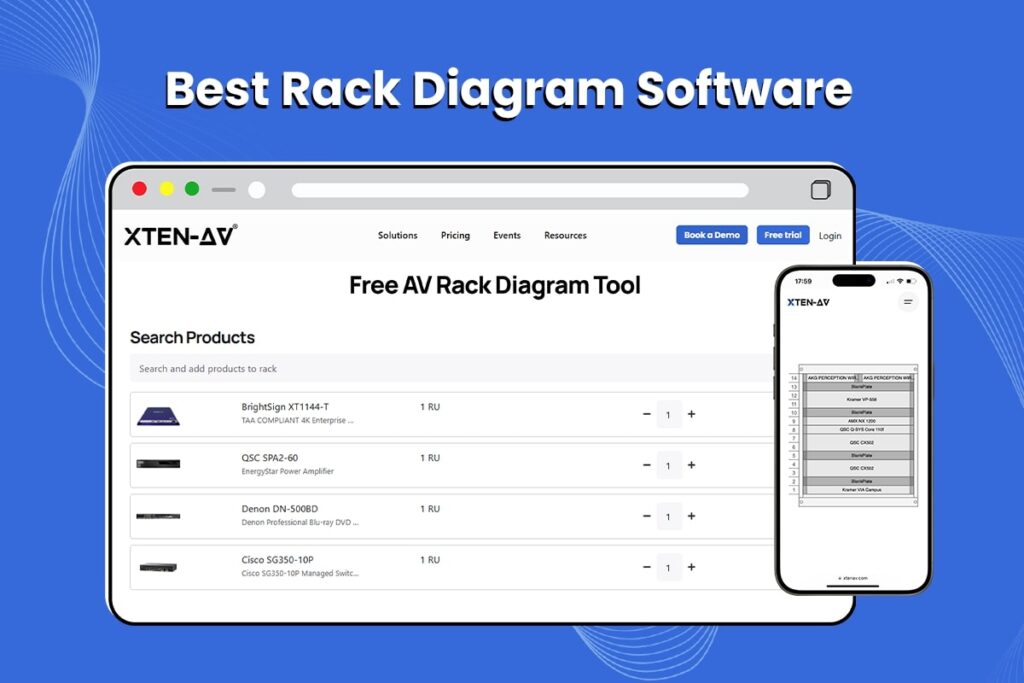

Choose XTEN-AV for effective cable management. It creates detailed cable lists during design with its AV Rack Diagram builder. The platform helps avoid mistakes, keeps cables connected, and provides visual guides for AV rack layout and future repairs.

Exceeding Load Capacity

When a rack is overloaded, it might break, overheat, or cause equipment to fail. This mistake happens when you plan poorly, neglect equipment weight, or forget to plan for future growth.

Avoid this by carefully calculating the total weight and power needs of all equipment before installation. Follow the rack manufacturer’s guidelines and space out heavy items evenly to keep the rack balanced and safe. Ensure the rack has proper ventilation to maintain a cool environment and monitor the power consumption of your system.

Skipping Documentation of Cable Runs

Skipping cable run documentation is a common AV rack wire management mistake. It makes it hard for technicians to trace cable paths, sources, and destinations. Therefore, making system modifications or repairs will be inefficient and error prone. This will also raise potential problems with future scalability and compliance with industry standards.

To avoid these issues, write down details for every cable. Label both ends clearly. Note the cable type and where it goes. Keep your diagrams and records updated.

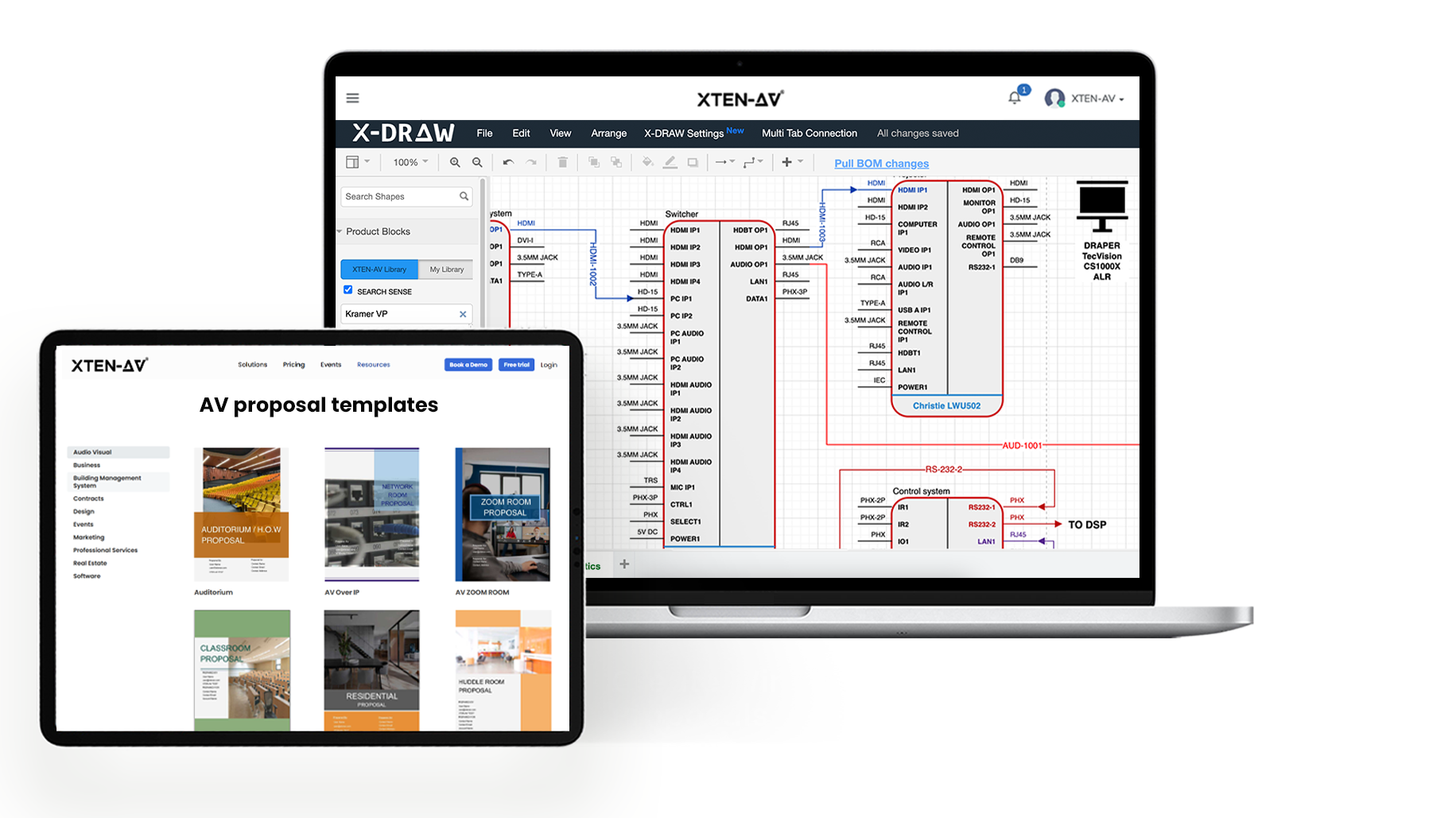

XTEN-AV helps AV professionals create, update, and print rack system diagrams in real-time. This makes documentation faster and easier. Whether you’re on-site or collaborating remotely, these visual diagrams keep your entire team aligned, reducing miscommunication, preventing errors, and boosting project timelines.

XTEN-AV makes sure every cable, connection, and component is clearly documented and easy to access. This removes the guesswork and helps integrators deliver consistent, professional results.

Not Testing Cables After Installation

Skipping post-installation testing can cause broken connectors, wrong wiring, or signal interference. This leads to long troubleshooting, project delays, and unhappy clients.

Check if the signal flows properly, watch for interference, and look for disconnected or crossed wires. Also, securely attach connectors. Test all cable types, audio, video, and data, and document the results as part of the installation record.

This approach helps you find and fix problems quickly. It ensures reliable performance and lowers the chance of costly callbacks.

Using Inconsistent Labeling Conventions or Color Codes

If labels are unclear or there are different styles and colors, technicians can’t find the cables. This slows down maintenance and system upgrades. This can lead to accidental disconnections, downtime, and costly errors, especially in complex or large AV installations.

The best practice is to establish and stick to cable labeling standards and color codes across all cables and equipment. Label both ends of every cable, make them readable, and use materials that won’t fade. Keep a record of what each label or color means and update if anything changes. This makes life easier for future maintenance.

XTEN-AV offers rack diagram software that automatically creates labels, ensuring everything remains consistent and professional. Plan how to label and color-code cables, document the system, and visualize everything directly in the software.

Not Preparing for Future Expansion

If your AV rack design only fits current needs and ignores future upgrades, you’ll face problems later. Fixing them will take more time and money. If you don’t plan for extra gear or future updates, your rack will run out of space.

This causes messy cables and expensive fixes to add new devices. This oversight can result in unnecessary downtime, increased labor, and higher long-term costs.

Think ahead about what you might need in the future and build your rack to accommodate it. Choose a rack slightly larger than you need now to fit future gear. Plan cable pathways that can handle extra cables.

How Can XTEN-AV Help You Avoid AV Rack Cable Management Mistakes?

Tired of tangled cables, overheating racks, and costly do-overs? You’re not alone. These common AV rack issues can slow down installs, frustrate teams, and damage your work. That’s exactly why AV professionals are turning to XTEN-AV.

XTEN-AV simplifies audio rack cable management with automation, AVIXA-compliant workflows, and real-time collaboration. From the start, the platform helps you avoid errors. It separates power and data lines to reduce interference, plans airflow to prevent overheating, reduces the risk, and allows space for maintenance and upgrades.

- XTEN-AV helps plan AV racks precisely. It prevents overloads and ensures scalable, standards-compliant layouts from the start.

- Automatically separates power and data cables in your rack design to reduce interference and maintain clean, reliable signal flow.

- Accounts for heat generation and airflow needs, helping you avoid equipment damage and maintain optimal rack performance.

- Auto-generates professional labels for every cable and component, streamlining installation, documentation, and troubleshooting.

- Enables real-time collaboration, keeping all stakeholders aligned with live project updates and shared access to designs and documentation.

No more guesswork. No more rework. With XTEN-AV, every rack unit is built for performance, reliability, and future upgrades. You save time, cut down on errors, and deliver polished, professional results that your clients will trust.

With XTEN-AV, you’re not just managing AV racks but future-proofing them.

Start Your Free Trial or Book a Demo and see it in action.

AV Design Mastery + Winning Proposals = 10x Productivity!

- ✔ Automatic Cable Labeling & Styling

- ✔100+ Free Proposal Templates

- ✔ Upload & Create Floor Plans

- ✔1.5M Products from 5200 Brands

- ✔ AI-powered ‘Search Sense'

- ✔Legally Binding Digital Signatures

Conclusion

Poorly managed AV rack wiring can derail even the best system setup. Mistakes like not labeling cables, using the wrong cable lengths, overloading the rack, or forgetting to document everything can cause big problems like delays, equipment issues, or safety risks.

XTEN-AV helps solve these problems. It offers automated tools for planning cable layouts, labeling, organizing, and tracking everything in real time. This makes it easier for AV professionals to avoid errors and create clean, efficient, and future-proof setups.

Use XTEN-AV for your next AV rack cable management solution to manage cables more effectively and keep your projects running smoothly.

FAQ's

For AV cable routing, plan ahead and measure the cable path. Use the right cable length to avoid extra slack and separate power cables from data cables whenever possible. Label each end of all cables.

Next, bundle cables by type or destination with Velcro straps. Use management bars or trays to keep pathways tidy.

Leave some space between all bundles for airflow so cables don’t touch each other. Finally, check the connections are correct as soon as you install them to catch any issues early. This will help with your AV rack cable management.

Minimizing cable clutter improves airflow, reducing overheating risks. It makes troubleshooting and maintenance easier, boosts system reliability by preventing accidental disconnections and interference, and creates a clean, professional look that supports scalability.

A neat rack improves safety by removing tripping hazards and reducing strain on connectors. It also speeds up plugging and unplugging, lowers costs, saves time, and ensures long-term performance.

Explore more by topic

AV Design Mastery + Winning Proposals = 10x Productivity!

- Automatic Cable Labeling & Styling

- 100+ Free Proposal Templates

- Upload & Create Floor Plans

- 1.5M Products from 5200 Brands

- AI-powered ‘Search Sense'

- Legally Binding Digital Signatures

No Credit Card Required

Related Blogs

-

- Posted by Sahil Dhingra

Audio Visual Top 5 Project Management Software CRM & Invoicing Tools for...

-

- Posted by Sahil Dhingra

Audio Visual Paging and PA System Cost Estimation Guide Sahil Dhingra Published...

-

- Posted by Sahil Dhingra

Audio Visual Security Site Survey for System Design & Integration Checklist Sahil...